[ad_1]

With the gradual movement of the world from gas-powered engines to a more sustainable and cleaner mode of transportation, the need for constant development of battery technology is paramount. Battery technology is crucial in electric vehicles becoming more viable. Companies have aimed at improving the energy density of batteries, so they can store more energy per unit of weight. Previously, lithium-ion batteries could store 100 Wh/kg; today, this figure has gone as high as 200 Wh/kg. With this new development electric vehicles have been able to travel much farther on a single charge while remaining as light or even lighter than before with a significant reduction in battery costs. Batteries originally cost about $1,000/kWh. Today, that cost has dropped to about $100/kWh, leading to the reduction of the overall cost of the production of an EV. Another significant improvement is the massive decrease in charging times. With the new 800-volt charging architecture, electric vehicles can now charge from 0- to 80-percent in as little as 30 minutes. The long waiting times of before have been cut. These advancements in battery technology have attracted a section of the automobile industry that was before time skeptical. Some companies, however, have been at the forefront of these improvements in battery technology.

1 Tesla

Photo of a Tesla Model Y SUV cruising

Tesla has produced extremely powerful and energy-dense batteries putting them at the forefront of lithium-ion battery innovation. For instance, the 100 kWh battery pack of Tesla’s Model S is one of the largest in the industry, and this allows it enough energy to push it to 402 miles on a single charge, equipped also with a 370-volt architecture, that can produce about 1,000 amps of power. The battery of the Model Y has a unique design that makes use of multiple battery modules to send power to its electric motors. It can regulate temperature and protect the battery from extreme conditions due to its advanced thermal management system. Tesla also produces heavy-duty batteries for home use including the 13.5 kWh Powerwall for power outages and emergencies and the 3 MWh Megapack grid-scale energy storage solution.

2 LG Chem

A front three-quarter action shot of a Chevrolet Bolt EV driving

LG Chem has been one of the front-runners in battery technology. It has produced batteries that have powered everything from consumer electronics to electric vehicles. The company has been instrumental in the drive of transitioning energy generation from fossil fuels two renewable and sustainable energy. The company has produced batteries for electric vehicle manufacturers for years including GM, Volvo, and Ford. One of its most prominent and highly-regarded batteries is the lithium-ion battery it produced for GM’s Chevrolet Bolt, which is highly efficient and produces a range of up to 259 miles. Recently, LG Chem developed a renewable energy storage system which they call the Resu 10H. It can store excess solar energy for future use. Their experience and impact in the industry have led to massive improvements in electric vehicle battery technology.

3 Panasonic

Front 3 quarter shot of a black 2014 Tesla Model 3 on a track.

Panasonic is another perennial well-known name, that has had a strong track record of innovation in battery technology. The company has been producing batteries that have been used in a wide range of applications, including electric vehicles as well as home energy storage systems. For a long time, Panasonic has partnered with Tesla to build battery packs for its electric vehicles including the battery packs of the Model S, Model X and Model 3. These two companies are currently partnering to build a more efficient, more cost-effective, and long-lasting battery which is called the “Million-Mile Battery“. They also partner with Tesla to produce Tesla’s Powerwall. Their focus on sustainability and efficiency has positioned them as a key player in the race towards reshaping energy generation of the future towards being more efficient and sustainable.

4 Samsung SDI

Side view of a white 2023 Audi E-Tron

Samsung SDI’s batteries are being used in different applications including smartphones and electric vehicles. Samsung SDI has partnered with automakers such as GM, BMW, Audi, and Volkswagen to be a major supplier of batteries for their electric vehicles. The company has also developed a high-capacity battery called the “High-Capacity E-bus Battery” specifically for use in electric buses. Its capacity of up to 441 kWh can power a bus for as long as 186 miles. This high-capacity battery is primarily designed to be reliable as well as efficient, making it a great option for transit agencies looking to reduce their carbon footprint. Electric vehicles like the BMW i3, the Audi e-tron electric SUV and the Volkswagen e-Golf are examples of beneficiaries of Samsung SDI’s battery technology. Home energy storage systems like the ESS are produced by Samsung SDI.

5 CATL

Front Angle Shot Of A Blue Volkswagen-ID.4

Contemporary Amperex Technology Co. Ltd. (CATL) is known for innovative research and development in the creation of high-capacity batteries. These batteries have higher power output and longer ranges than conventional batteries. The 400-mile range battery being used by the Nio ES8 is one of CATL’s most notable achievements. It has a capacity of 84 kWh and is popular in China due to its affordability and impressive performance. The company is also known for its development of the world’s first cobalt-free lithium-ion battery. This battery is lighter and more sustainable than conventional batteries. The highly practical and efficient Volkswagen ID.4 also uses CATL batteries. As the demand to transition to cleaner and more sustainable energy continues to grow, the company has continued to expand into other areas like energy storage systems for businesses and homes.

6 BYD (Build Your Dreams)

Front three quarters of a white stationary Ford Kuga PHEV

BYD, a Chinese company, is known to produce reliable batteries ranging from small capacitors to large-scale power stations. It produces excellent batteries like the very advanced lithium-iron-phosphate battery called the Blade Battery which is highly efficient. It offers improved safety and a much higher energy density than conventional batteries. This battery is in BYD’s Han EV which is produced and sold primarily in China. It has a range of 376 miles on a single charge. In addition to this, the company has also produced batteries for Ford and Daimler. Notably, Ford’s Kuga PHEV which produces an all-electric range of 35 miles is one example. BYD’s Iron-Phosphate Battery System is designed to be highly efficient, reliable and for commercial and industrial use. Its capacity of 1.2 MWh makes it one of the largest energy storage systems available today.

7 SK On Co. Ltd

2023 Hyundai Kona Electric’s front fascia

The company’s portfolio is made up of highly innovative batteries which include the cylindrical cell which has been highly accepted and adopted by EV manufacturers like Hyundai. This cylindrical cell is currently being used by vehicles like the Hyundai Kona Electric, the Kia Niro, and the discontinued Kia Soul EV. The 64 kWh battery pack available inside the Hyundai Kona Electric comprises 294 cylindrical cells made by the company. A higher energy density pouch-type battery is produced by SK On Co., Ltd. It has improved thermal stability and can be used in different applications, including electric vehicles and energy storage systems. In addition to this, the company also makes sure its batteries are made up of recyclable materials that make sure the reduction of deposits in landfills and an increase in the recycling culture.

8 A123 Systems

Front three-quarters shot of a burgundy Fisker Karma parked

A123 Systems has innovative battery designs that are rapidly helping in transitioning the world towards electrification. Built by A123 Systems, the nanophosphate lithium-ion battery, offers superior power, safety, and long life. Alongside the FIA Formula E racing series where the nanophosphate lithium-ion battery delivers impressive performance on the racetrack, the Fisker Karma which was produced from 2011 to 2012 used a 20.1 kWh A123 Systems nanophosphate lithium-ion battery. The Chevrolet Spark which was produced between 2013 and 2016, was also powered by a 19 kWh A123 Systems nanophosphate lithium-ion battery. A123 Systems also develops batteries for electric buses like the battery packs in Proterra buses that have a range of up to 300 miles on a single charge. The company is currently working on building batteries that will be used in heavy-duty trucks and other commercial vehicles.

9 NEC Energy Solutions

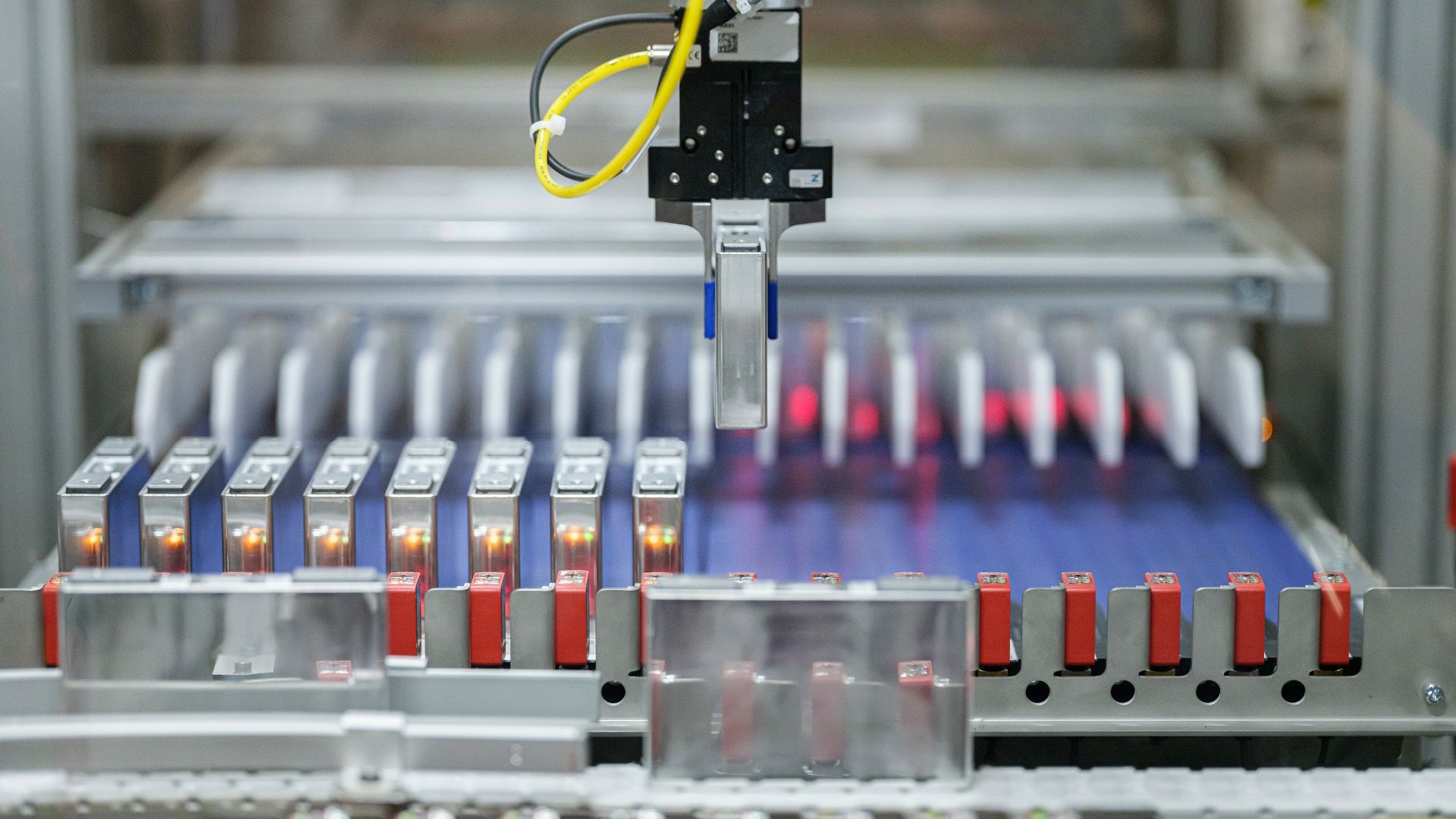

BMW battery cell coating process

This company does not produce batteries for electric vehicles rather it produces energy storage solutions as well as battery packs for electric ferries and trains. The company produces high capacity, large energy density, long life batteries for industrial and commercial use. These batteries are used together with residential solar installations. The GSS (Grid Storage Solution), NEC Energy Solutions’ brain-child, is a modular configurable energy system designed to be highly scalable as well as help grid operators integrate renewable energy resources into the grid. The Sterling Municipal Light Department (SMLD), Southern California Edison (SCE), and Hokkaido Electric Power Company are just a few examples of the places where the NEC Energy Solutions’ Grid Storage Solution has been used. With the rapid development of EV battery technology, this kind of scale should soon translate to EVs.

10 Envision AESC

Front three-quarters shot of a Karma GS-6

Envision AESC is a battery manufacturer that partners with Nissan, Renault, Daimler AG, and Karma Automotive to produce electric vehicle batteries. The company produces the Ternary lithium-ion battery which is a combination of nickel, cobalt, manganese, and lithium in the cathode of the battery. It also builds the LFP (Lithium Iron Phosphate) and NMC (Nickel Manganese Cobalt) batteries which are used in both electric vehicles and energy storage systems. The 40 and 62-kWh lithium-ion battery packs inside the Nissan Leaf and Leaf Plus models are produced by Envision AESC. Envision AESC announced in 2022 an agreement with Daimler AG to supply batteries for its Mercedes-Benz electric vehicles from 2025. They will be produced at Envision AESC’s new battery plant in Wuxi, China, which is expected to produce 300 gigawatt-hours (GWh) of batteries by 2030.

[ad_2]

Source link